Samruddhi Pande

AISSMS College of Pharmacy

What if I tell you that we could 3D print your personalised pill or infact a polypill at home? Surprised? Intrigued? Wondering if that is even possible?

Well, pause here. Now let me take you to the future of Pharmaceutical Medications!

Today, we somehow still live in the world of trial-and-error, empirical medicines; but more importantly we are also in the world of proactive health. Almost every second hand wears a smartwatch which detects heart rate, blood pressure, the number of steps walked each day, and reminds to drink water too; some even have EKG set up in their watches. Clearly it eases life.

Nevertheless, technology is not only confined to diagnosis but now can also be used in making Medicines! Shelving the regular methods of formulating pills, tablets, capsules with Tablet press, Compression Granulation or Plate Process, the world is swayed by Technology! One of the technologies that is evolving is 3D Printed Medicines!

In 2015, Aprecia Pharmaceuticals SPRITAM (levetiracetam) was approved by the U.S. Food and Drug Administration (FDA). It was the first 3D printed prescription drug to treat partial onset seizures, myoclonic seizures and primary generalized tonic-clonic seizures brought on by EPILEPSY. They developed ZIPDOSE, a patented technology for 3D printing drugs to enable high-dose medications in a rapidly disintegrating form.

How does it work?

The printer lays down very thin sheets of powdered medication blended with water based fluid. It then binds these layers at the microscopic level enabling to squeeze in the most of the Active ingredients. This results in layers and layers of Precision with highly porous, solid oral dispersible medication.

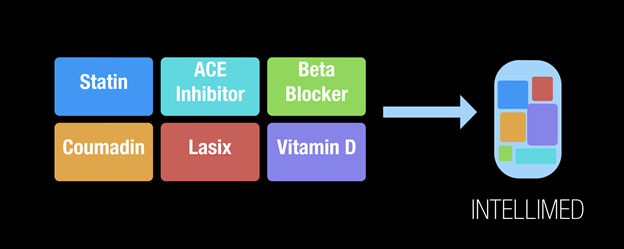

Technology can do much more today. 3D printers could combine multiple fixed-dose formulations, with each having its individual unique release-profile and properties, a POLYPILL!

For example, instead of taking 6 medications, you could integrate or combine them into one, each having its own properties.

Why 3D Printed Medicines?

- They are more efficient than traditional manufacturing.

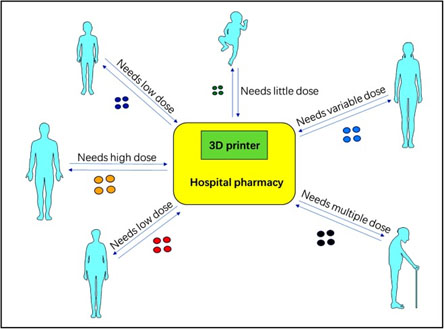

- The printers could be located in pharmacies; it would allow doctors and pharmacists to tailor tablets for those patients who would benefit most (including children and elderly and individuals having difficulty in swallowing).

- Based on the diagnosis, treatment and treatment plan, the doctors or pharmacists could print the drug on the spot to adapt to the specific situation of each patient.

4. 3DP is a highly flexible process that allows you to design the size of the pill or filling percentage to precisely control the dosage that meets each patient’s individual needs.

5. It could produce 10 different printlets shapes, and has proved that these printlets could improve the acceptability of solid oral drugs to patients.

Technologies used in process of 3D Printing Medicines:

- Fused Deposition Modelling (FDM): Filaments loaded with medicines can be used for the manufacturing of the pills.

- Direct Power Extrusion: It is similar to ZIPDOSE but is patented under FABRx.

- Stereolithography (SLA): It uses photopolymers for the solidification of resins or liquid materials.

- Selective Laser Sintering (SLS): The mixture of active ingredients with some copolymers fused by a laser.

- InkJet Printing: Combinations of active ingredients and excipients or inks are sprayed through the nozzle. It creates the structures layer by layer and gets solidified with the aid of a powder substrate which is then sprayed.

Coming back to present-

In spite of the fact that 3D Printed Medication is still in the early stages of development, we cannot deny its velocity.

Fred Paretti from Multiply Labs once said regarding 3D Printed Medications,

“In ten years’ time no patient will agree to take the same thing as another millions of people. And no doctor will prescribe the same thing to two patients“.

A last concluding tap on 3D printing medication –

3D printing overcomes the limitations of conventional formulation techniques in tailoring the tablet’s microstructure and changing composition in different regions. It makes it possible to print tablets with different release responses and also gives power in the hands of the consumers, giving them medications specifically constructed for them. But with this power, also come the liabilities, rules and legislation to maintain the power at balance! Hence, conscious work is demanded.

If this fascinates you, you can know more about 3D printing medications from the YouTube links below:

- https://m.youtube.com/watch?v=-RkhAP0_ms4

- https://www.aprecia.com/technology/zipdose

- https://m.youtube.com/watch?v=ePVFasXDi68

- https://m.youtube.com/watch?v=FGpbiJxkkak

References:

- https://all3dp.com/2/3d-printing-drugs-the-latest-advancements-around-the-world/

- https://www.sciencedirect.com/science/article/pii/S0753332220308374

- https://www.aprecia.com/technology/zipdose

- https://www.ted.com/talks/daniel_kraft_the_pharmacy_of_the_future_personalized_pills_3d_printed_at_home?language=en